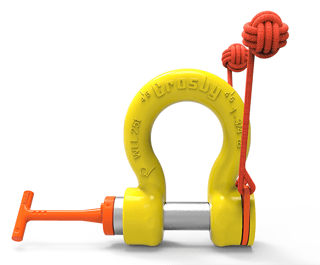

Crosby Introduces ROV Release & Retrieve Shackle Line Featuring the Patent Pending Captured Bolt Design

(Tulsa, OK) After years of development and intensive testing by several of the top subsea specialists in the world, the new Crosby ROV Release and Retrieve Shackles are ready for global release. Featuring an innovative Patent Pending Captured Bolt design, which prevents bolt detaching from the shackle bow, the release and retrieve shackle eliminates the need to have one shackle for releasing a load and one shackle for retrieving a load, and reduces end user liability by eliminating costly post-purchase modifications (i.e., capture barrels, springs, or tether cables). The shackles are available in two different bolt designs: QUIC-Thread (G-2100) and Non-Threaded (G-2110). The QUIC-Thread option requires 60% fewer turns than conventional threaded screw pin type shackles, while the Non-Threaded option touts one of the fastest release and retrieve times in the industry. Designed by the end user for the end user, these best-in-class shackles also feature:

new Crosby ROV Release and Retrieve Shackles are ready for global release. Featuring an innovative Patent Pending Captured Bolt design, which prevents bolt detaching from the shackle bow, the release and retrieve shackle eliminates the need to have one shackle for releasing a load and one shackle for retrieving a load, and reduces end user liability by eliminating costly post-purchase modifications (i.e., capture barrels, springs, or tether cables). The shackles are available in two different bolt designs: QUIC-Thread (G-2100) and Non-Threaded (G-2110). The QUIC-Thread option requires 60% fewer turns than conventional threaded screw pin type shackles, while the Non-Threaded option touts one of the fastest release and retrieve times in the industry. Designed by the end user for the end user, these best-in-class shackles also feature:

- Forged alloy, galvanized bow with durable API RP 17H color-compliant epoxy finish

- 6 to 1 Design Factor

- Robust captured bolt design - can withstand over 2,000 lbs. of pull-out force

- Galvanized alloy bolt – available in two designs: QUIC-Thread and Non-Threaded

- API RP 17H compliant modular handles available in T, D, F, or Eye versions (sold separately)

- Durable secondary locking latches for added securement

- Eyelets forged into bow for optional tether points

- Monkey Fist(s) included

- Made in the USA

Available in 7 different sizes: 9.5t, 12t, 17t, 25t, 35, 55t, and 85t. These shackles are job site tough and are sure to save you both time and money.

- No costly modifications required (like capture barrels or tether lines), thus reducing end user liability.

- One shackle does it all: releases and retrieves without the need to resurface.

- Both the QUIC-Thread and Non-Threaded bolts greatly reduce the time on the job, saving you costly man hours and vessel time.

For more information on this innovative new product line stop by your local Crosby Distributor.

Infrastructure. Mark will be based out of Montreal, Canada and will be supporting our distributors globally, through the development of strategies to drive Crosby specification, product awareness, and Crosby brand preference at key accounts in the Infrastructure Sector.

Infrastructure. Mark will be based out of Montreal, Canada and will be supporting our distributors globally, through the development of strategies to drive Crosby specification, product awareness, and Crosby brand preference at key accounts in the Infrastructure Sector.

- Product Trainer working in the Sales Department. James will be based out of Illinois and will be tasked with supporting the Crosby distribution channel in the Illinois, Iowa, Eastern Wisconsin, and Northern Indiana markets. James will develop strategies to penetrate end-user markets to drive specifications, support product awareness through Crosby’s World-class training programs, and support brand preference for Crosby products throughout his territory. This will in turn drive increased demand through our distributorship channels, and support end user efforts throughout the territory.

- Product Trainer working in the Sales Department. James will be based out of Illinois and will be tasked with supporting the Crosby distribution channel in the Illinois, Iowa, Eastern Wisconsin, and Northern Indiana markets. James will develop strategies to penetrate end-user markets to drive specifications, support product awareness through Crosby’s World-class training programs, and support brand preference for Crosby products throughout his territory. This will in turn drive increased demand through our distributorship channels, and support end user efforts throughout the territory.  Trainer working in the Sales Department. Luke will be based out of Connecticut and will be tasked with supporting the Crosby distribution channel in the Northeast. Luke will develop strategies to penetrate end-user markets to drive specifications, support product awareness through Crosby’s World-class training programs, and support brand preference for Crosby products throughout his territory. This will in turn drive increased demand through our distributorship channels, and support end user efforts throughout the territory.

Trainer working in the Sales Department. Luke will be based out of Connecticut and will be tasked with supporting the Crosby distribution channel in the Northeast. Luke will develop strategies to penetrate end-user markets to drive specifications, support product awareness through Crosby’s World-class training programs, and support brand preference for Crosby products throughout his territory. This will in turn drive increased demand through our distributorship channels, and support end user efforts throughout the territory.  new Crosby ROV Release and Retrieve Shackles are ready for global release. Featuring an innovative Patent Pending Captured Bolt design, which prevents bolt detaching from the shackle bow, the release and retrieve shackle eliminates the need to have one shackle for releasing a load and one shackle for retrieving a load, and reduces end user liability by eliminating costly post-purchase modifications (i.e., capture barrels, springs, or tether cables). The shackles are available in two different bolt designs: QUIC-Thread (G-2100) and Non-Threaded (G-2110). The QUIC-Thread option requires 60% fewer turns than conventional threaded screw pin type shackles, while the Non-Threaded option touts one of the fastest release and retrieve times in the industry. Designed by the end user for the end user, these best-in-class shackles also feature:

new Crosby ROV Release and Retrieve Shackles are ready for global release. Featuring an innovative Patent Pending Captured Bolt design, which prevents bolt detaching from the shackle bow, the release and retrieve shackle eliminates the need to have one shackle for releasing a load and one shackle for retrieving a load, and reduces end user liability by eliminating costly post-purchase modifications (i.e., capture barrels, springs, or tether cables). The shackles are available in two different bolt designs: QUIC-Thread (G-2100) and Non-Threaded (G-2110). The QUIC-Thread option requires 60% fewer turns than conventional threaded screw pin type shackles, while the Non-Threaded option touts one of the fastest release and retrieve times in the industry. Designed by the end user for the end user, these best-in-class shackles also feature: