|

It’s one thing to read about how Crosby sets the standard for the highest-quality rigging and lifting products in the industry—it’s another thing entirely to see it.

Each image features the world-renowned Crosby Red Pin® shackle at work during three subsea projects in the Gulf of Mexico. All images have been provided courtesy of First Subsea—the world's leading supplier and developer of ball and taper Ballgrab® connectors for subsea applications. |

Pompano Field J-Tube Riser Recovery The Pompano field, operated by Stone Energy, is an oil and gas production hub in the Gulf of Mexico that is thriving with subsea expeditions and subsequent Crosby product use. These images show Crosby G-2140 alloy bolt-type shackles (4-inch 175-ton working load limit and 1 ½-inch 30-ton working load limit) being used in conjunction with a First Subsea Ballgrab® pipeline recovery tool to successfully recover a 12-inch (30-cm) API 5L X65 J-tube riser. |

The Gulf of Mexico: 2,400 Feet (732 Metres) DownWith oil production in the Gulf of Mexico expected to rise significantly over the course of the next two years, the subsea sector will be a critical component of this growth. Successful subsea operations require reliable equipment that can tolerate sustained, repetitive exposure to underwater conditions at various depths. The following images illustrate the reliability of Crosby shackles 2,400 feet (732 metres) below the surface of the ocean in the Gulf of Mexico. In this application, the shackle connects a wire to the lifting eye of a First Subsea Ballgrab® tool during a pipeline installation. Even far beneath the surface of the ocean, it’s easy to notice the shackle’s Red Pin®—the mark of Crosby quality. |

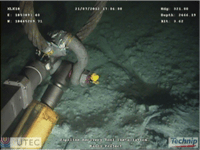

Hess Tubular Bells Field Pipe Lay

The Tubular Bells field, operated by Hess, is a deepwater oil and gas development in the Gulf of Mexico. In this image, a G-2160 “Wide Body” shackle (foreground) and a G-2140 alloy bolt-type shackle (background) are being utilized with a First Subsea Ballgrab® torque removal tool to achieve a pipe lay in the Tubular Bells field. |

The proof is in the picture: Crosby shackles set the subsea standard

Posted by Crosby on Apr 16, 2015 7:46:00 AM

Topics: Subsea