In the world of rigging and lifting, every minute detail—from latch securement to material transfer turning range—is critical to the success of an operation. When the safety of workers and the secure transport of valuable loads are on the line, it’s important to invest in the most dependable lifting equipment in the industry.

For Minnesota-based manufacturing company DCI, Inc., the decision to invest in the best meant choosing CrosbyIP non-marring lifting clamps for their lifting operations—a decision that has since reinforced a flourishing culture of safety and lifting confidence across the company.

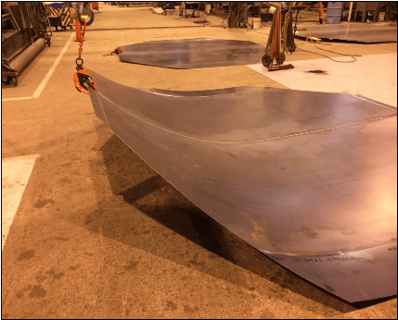

DCI is a global manufacturer of stainless steel tanks, vessels, agitators, and integrated systems, which requires the daily operation of lifting 600-pound to 1,800-pound units of stainless steel sheet metal. Until recently, this operation was achieved through the use of a lifting device developed in-house. However, due to the company’s concerns with employee safety, the decision was made to invest in new lifting technology, which was the pivotal moment that ultimately lead to DCI’s discovery of CrosbyIP lifting clamps.

During the process of researching various options for lifting clamps, DCI was approached by Dean Dearholt of Olsen Chain & Cable—a local overhead lifting equipment supplier and Crosby distributor. In meeting with DCI, Dearholt not only emphasized the importance of replacing the company’s outdated lifting devices, he also outlined the distinct advantages CrosbyIP non-marring lifting clamps have over the competition in the three areas of ergonomics, performance, and training:

Ergonomics: A CrosbyIP non-marring vertical lifting clamp with a one-ton working load limit has a mere weight of ten pounds, reducing strain on employees who use this equipment repeatedly throughout the day.

Performance: The polyurethane pads on CrosbyIP non-marring clamps will not mar or scratch a material’s surface.

Training: As a value-added feature, Crosby offered to send a trainer to DCI to instruct employees on the correct, safe usage of CrosbyIP non-marring lifting clamps.

Upon discovering the benefits, value-added features, and competitive advantages of CrosbyIP non-marring lifting clamps, DCI decided to choose Crosby as their partner for future lifting operations. The positive results of this decision were experienced immediately across the company.

Since switching to CrosbyIP non-marring lifting clamps, DCI employees received thorough product training (as promised by Crosby) and there have been no accidents due to increased safety and lifting confidence among employees. In addition, DCI is now considering expanding the use of CrosbyIP lifting clamps to other departments within the company.

The partnership formed between Crosby, DCI, and Olsen Chain & Cable is a prime example of the far-reaching impact Crosby products and services have in helping companies come together to succeed in their endeavors. When those who value lives and loads choose Crosby, the world of rigging and lifting becomes a stronger, safer, more secure industry.