CROSBY SHEAVE AND MACHINED SHANK HOOK CONFIGURATORS

“Hey Lou”, Stan said as he entered Lou’s office. “We have a problem with the hook in the block on the No. 2 crane.”

Lou looked up and replied, “What happened? Did someone get hurt?”

“Not yet”, Stan continued, “but if we don’t get it fixed, they might. It is old and worn, loose in the housing, the latch no longer engages as it should, and the guys on the floor are worried about it.”

“We need to get it fixed then”, Lou replied, “Get with Ruth in purchasing, tell her what you need, and have her get a quote from our Crosby distributor.”

Stan continued, “Well I know what I need, but the thing is so old, we do not have any good drawings showing the machine details. Every time I try to explain such details verbally to Ruth, something gets lost in the process.”

“This is your lucky day Stan” Lou replied. “The Crosby Rep was in the other day,” Lou continued, “and told me about these tools they have on the Crosby website, something called ‘configurators. They have one for sheaves and another for machined shank hooks. I used the one for sheaves yesterday. You make choices defining your requirements and in the end you get a drawing to pass along to purchasing. Helps you get exactly what you need. Here is the web address, give the shank hook one a try.”

“Thanks Lou.” replied Stan, “I will get right on it.”

Later that day...

“Thanks for the info Lou”, Stan said as he walked into Lou’s office. “I took your suggestion, visited Crosby’s website, used the configurator, spec’d out my hook requirements, and took the output drawing to Ruth. She is placing the order this afternoon. Like you said it was an easy process and Ruth has exact specifications to place the order with.”

Crosby configurators guide you through the process of specifying your requirements for machined shank hooks and sheaves. Following a structured path, the configurators allow you to get the equipment you need, while using common components that are used throughout the Crosby Product line, and providing detailed information of your requirements at the end of the process, which can be used for procurement. Crosby configurators, another “Value Added Resource”.

Click here to access our configurators from the Crosby website.

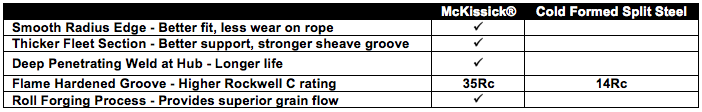

DO NOT BE FOOLED… into thinking all sheaves produce the same results.

Every McKissick roll-forged sheave starts as a single piece of AISI C-1035 carbon steel plate. Utilizing a "time proven" proprietary roll forging process that adds extra strength to the critical groove section, the sheave is formed from a precision flame cut blank. The hub is then pressed into place with complete metal-to-metal contact and secured with a deep penetrating weld to ensure proper fit and longer life. Before the McKissick name is added, each sheave is thoroughly inspected to meet applicable industry and Crosby quality standards.

Click here to learn more about the critical standard features and elements of a superior McKissick Roll-Forged sheave.

Brasil Offshore 2015

June 23-26, 2015

Macae, Rio De Janeiro, Brasil

Macaé Centro

2015 API Offshore Safe Lifting Conference & Expo

July 14-15, 2015

Houston, TX USA

Westin Houston Memorial City