In the world of rigging, many loads or machinery are fitted with weld-on permanent lifting points (pad eyes) that are used to connect to rigging hardware and slings. Often, the rigging hardware of choice to connect the sling to the pad eye is a Crosby shackle.

Important points to consider

Note: The recommendations below are for Crosby shackles only, and should not be interpreted as recommendations or criteria for pad eye design. There are many factors that must be taken into consideration during pad eye design that are not part of this article.

- Although Crosby shackles can be point-loaded on the shackle pin when the load is kept reasonably centered, it is always recommended that the pad eye be designed so that the eye width is 50% to 80% minimum of the width of the exposed shackle pin between the ears of the shackle bow. Thus, it is recommended that the loading be distributed across at least half of the exposed length of the shackle pin.

- If pad eye width is 50% or less than the spread between the shackle ears, it is important that the user keeps the load reasonably centered on the shackle pin. Spacers can be used to keep the load reasonably centered on the shackle pin.

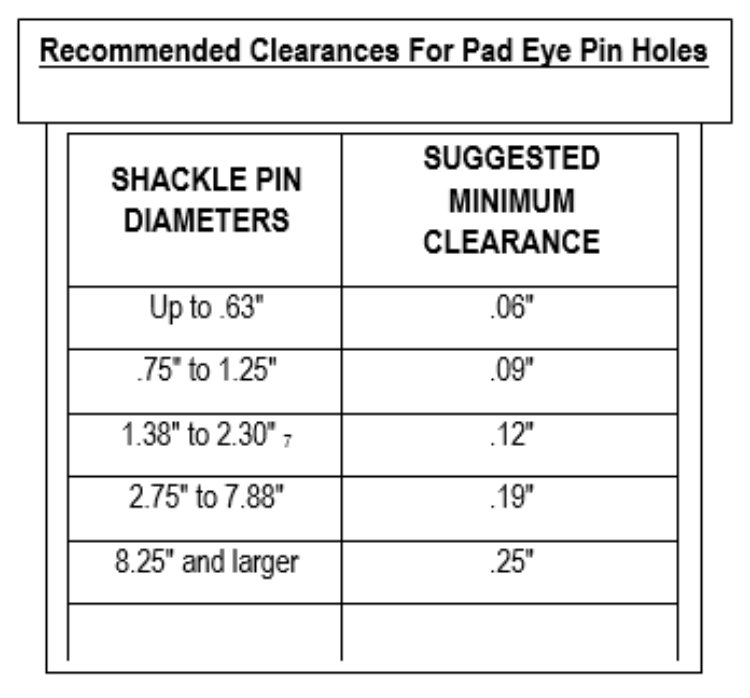

- During the design process of the pad eye, the appropriate size and style of shackle to be connected needs to be pre-determined and the pad eye hole must be drilled to a proper size diameter to ensure the shackle pin OD and Pad Eye ID allows for ease of pin insertion and provides adequate clearance for the shackle to perform properly without interference.

- The pad eye should not have any sharp edges in contact with the shackle pin.

- Ensure the shackle is a screw pin, or bolt, nut and cotter design.

- If it is a screw pin shackle, the pin must be tight and never backed off before use.

- If a screw pin shackle is used, the user must ensure that the shackle pin cannot unscrew or vibrate loose.

- Moussing of the shackle may be required to ensure the pin does not come loose during operation.

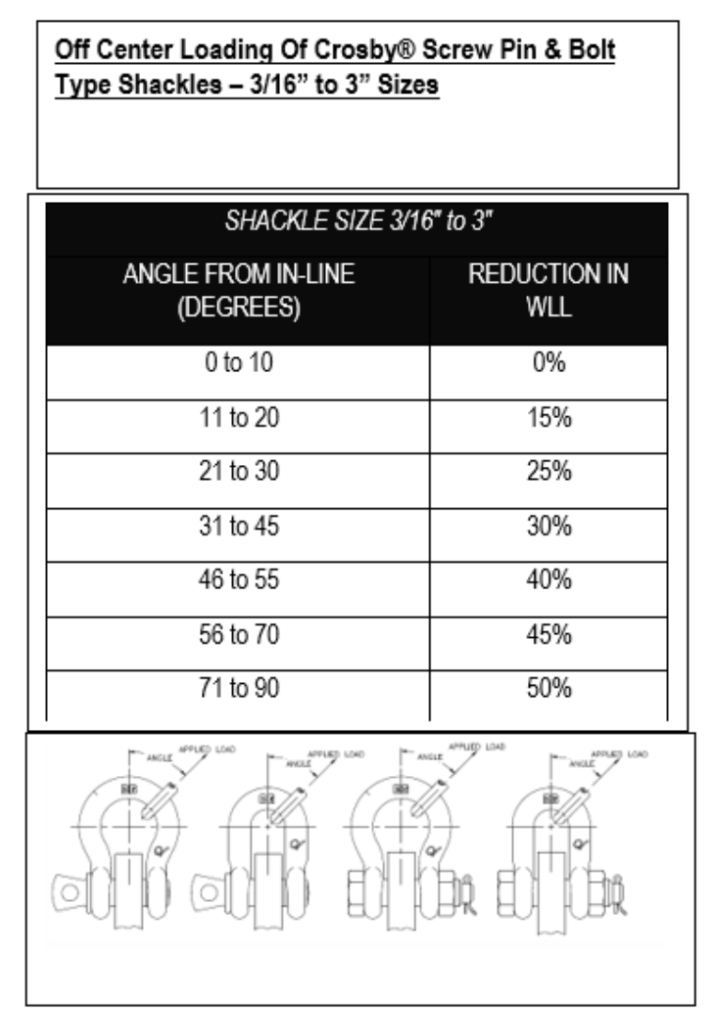

- The shackle’s working load limit must never be exceeded. If the shackle is subjected to a side load, then the shackle’s working load limit must be reduced per manufacturer’s recommendations.

- The shackle must be able to align itself with the sling leg or direction of loading without interference.

- If a bolt, nut, and cotter pin shackle is used, the user must ensure the cotter pin is in place at all times.

- If the shackle bow has a diameter larger than 3 inches, and the pad eye width is smaller than the shackle pin diameter, then the shackle’s working load limit must be reduced 15% due to potential side loading.

- ASME B30.26 states that a visual inspection shall be performed by the user or other designated person each day before the shackle is used. (See ASME B30.26 and manufacturers inspection guidelines for full details).

- Please call Crosby Technical Support at 1-800-220-8509 for additional information or assistance.

Rig safe!

– Danny

Danny’s Rigging Den is a blog series written by Danny Bishop, Crosby’s corporate director of value added training.